Do You Have A Machining Project We Can Help With?

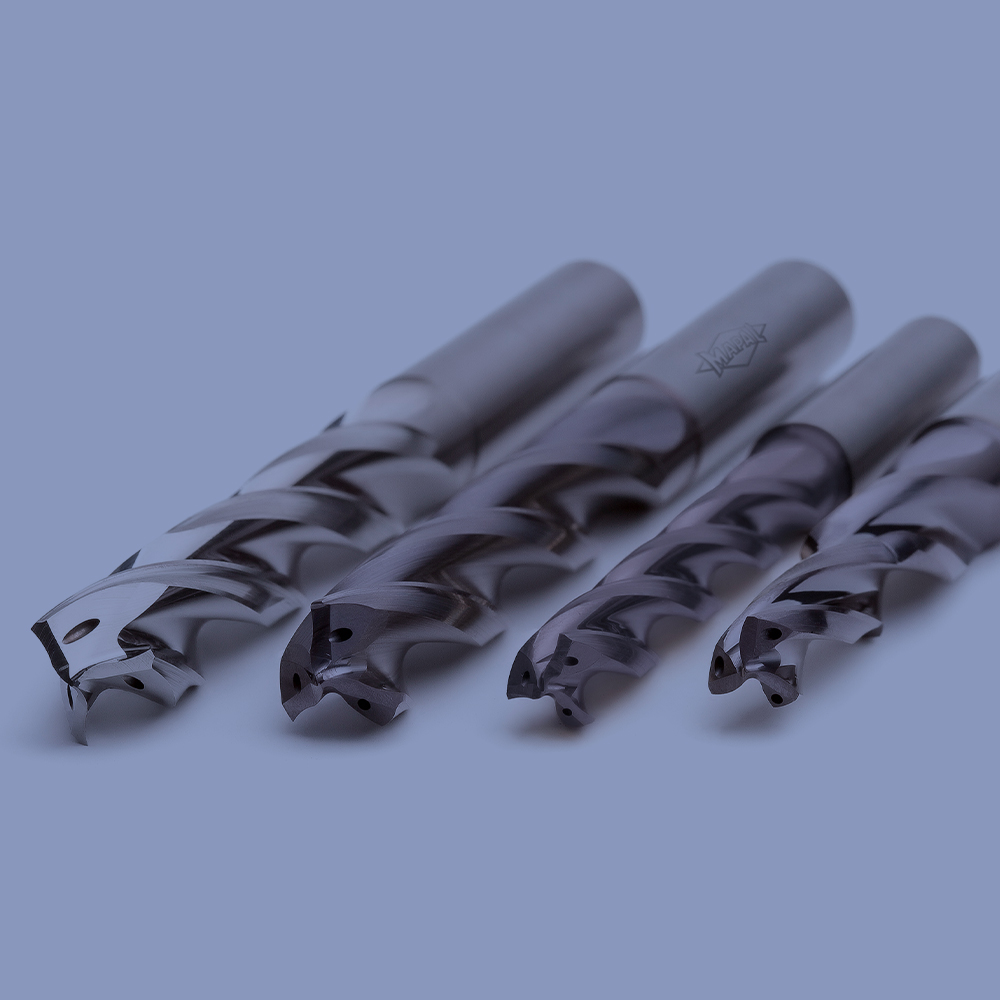

TTD Tritan-Drill and Pyramid tip QTD Drill

New Development

TTD-Tritan – Machining of heat exchangers taken to the next level !!

Many versions of heat exchangers are used in different industries. After all, they help to make heat generated usable for other processes. In the case of recuperators, two liquid or gaseous media with different temperatures are pumped into separate circuits. A heat exchange takes place without mixing the media. Recuperators include bundle heat exchangers, which are usually made of metal and consist of a tube bundle that conducts a medium and an orifice baffle with a front tube plate through which a second medium flows. Depending on the size of the heat exchanger, the front tube plate has a large number of bores. To ensure that the medium does not escape at this component transition, high requirements are set at the bores with regard to position accuracy and dimensional accuracy.

Triple edge drill is the method of choice

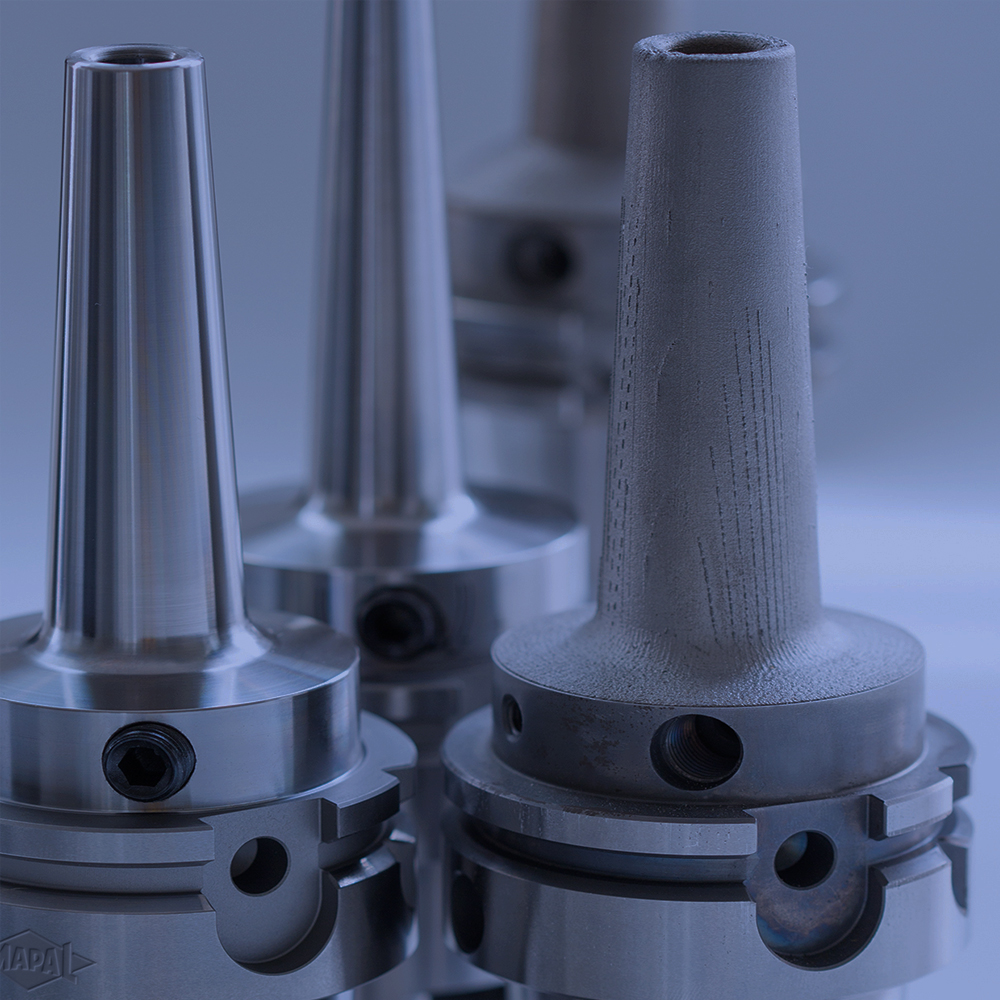

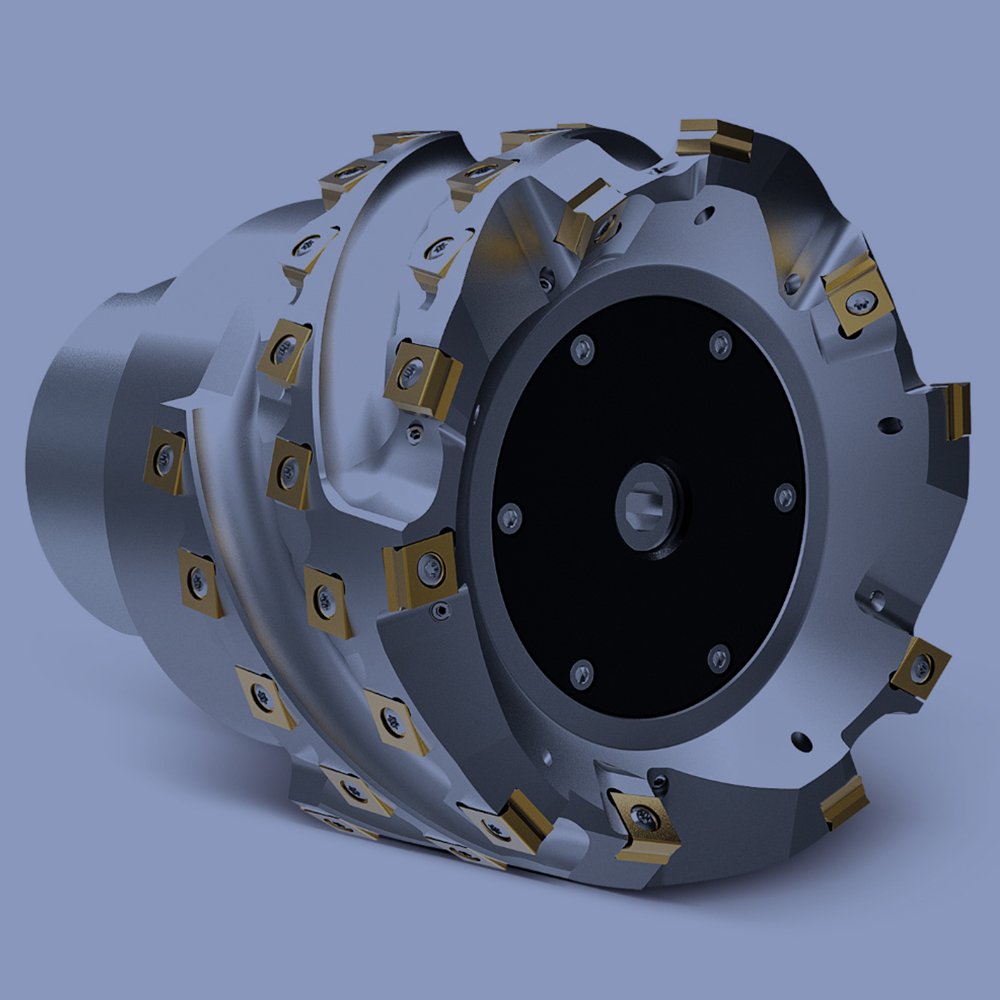

The triple edge replaceable head drill TTD-Tritan from MAPAL has been tested in the petrochemical industry and is convincing right down the line when machining a tube plate. On the TTD-Tritan, tool head and tool holder are joined by Hirth serration. This connection is easy to operate and particularly stable, so that all the drill reaches the performance level of the solid carbide equivalent. In addition it guarantees the best torque transmission with simultaneous high changing and radial run-out accuracy. The TTD-Tritan is optimally centred via its pronounced drill tip and ensures very good circularity. In addition, the cost-intensive carbide is limited to the tool head for the replaceable head system, which leads to low tool costs even with large diameters. The replaceable head system has a positive effect on stock, as the wear parts are mainly limited to the drill heads: As a result, the capital tied up in stock is also reduced.

In a specific case, the customer needs each diameter version in several lengths to machine the different versions of tube plates. The complete MAPAL range makes it possible to provide all desired versions. In addition, smaller diameters are served with the solid carbide design.

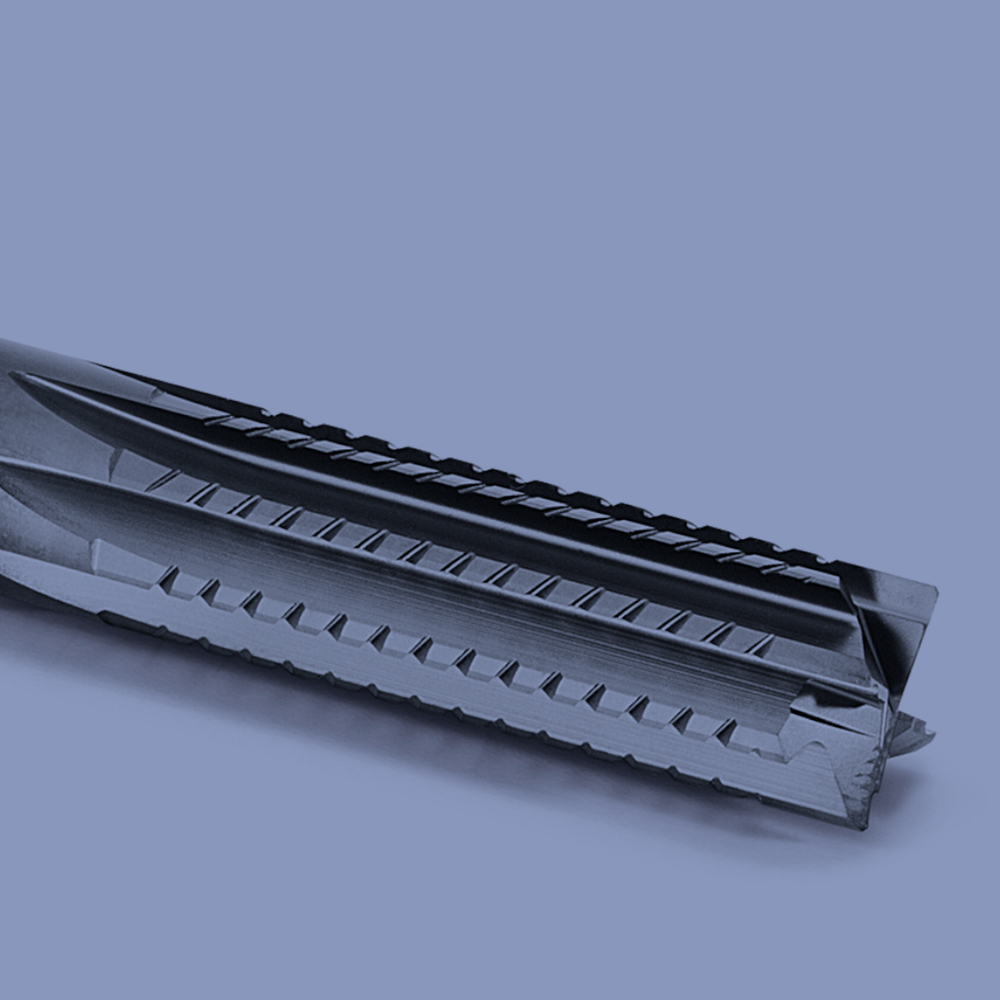

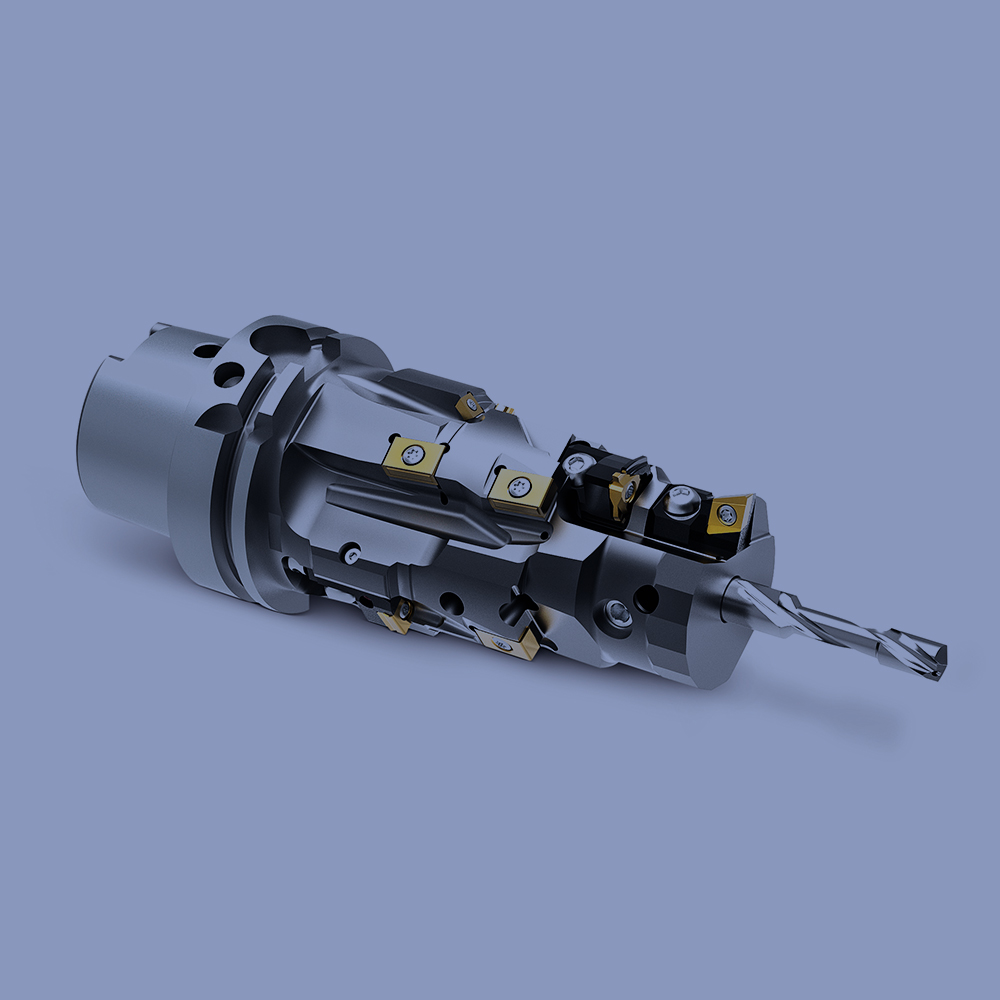

QTD indexable insert drill with new pyramid tip for stack machining

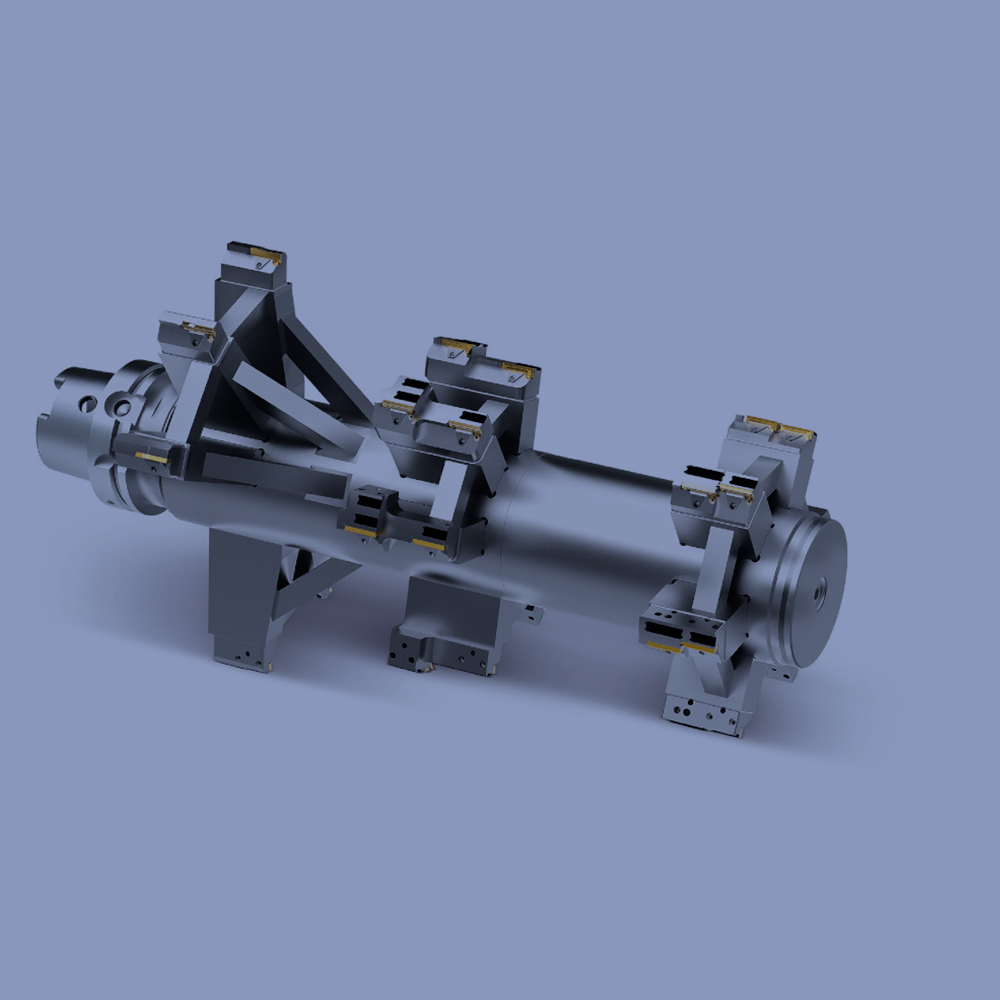

In addition to the two front tube plates, slightly thinner intermediate plates with the same bore pattern are also installed in shell & tube heat exchangers. These intermediate plates are stacked above one another for machining, spot welded together, drilled and then separated again. With the QTD indexable insert drill with innovative, patented pyramid tip, MAPAL has the optimum solution for even this application in its portfolio. The newly developed indexable insert with pyramid tip has a very small chisel edge and a tip angle of 120°. Furthermore, the indexable insert is self-centering and ensures a controlled bore entrance. The intermediate plates can thus be reliably drilled in a single machining step.

MAPAL Effect

The front tube plate of a heat exchanger has a large number of bores. Thanks to drills with Tritan geometry from MAPAL, machining is significantly improved in terms of economy, precision and performance.

The replaceable head drill TTD-Tritan with three cutting edges reaches the performance level of his solid carbide equivalent.

For machining the intermediate plates of the heat exchanger MAPAL has developed the QTD indexable insert drill with innovative, patented pyramid tip.

MAPAL Effect

Cost effective solution

Increase in productivity

Significant increase in the machining quality

High process reliability

The MAPAL Effect

When something exceptional develops between us:

That’s the MAPAL Effect.